VIBCO – The Crying Customer

By Karl Wadensten, CEO

The day began like any other at VIBCO, Inc. It was a Friday morning and our shop floor employees were looking forward to the start of their weekend, (they worked Monday through Thursday 7:30 to 5 so they could work just a half day on Friday). Then the Customer called. He needed our vibrators on site Monday. He had called earlier in the week to make sure they would ship express by Friday. He had gone through the long process of ordering and credit card approval and had made several calls throughout the day to check up on his vibrators order. As a small sub-contractor on the Sunshine Skyway billion dollar bridge project, his job was on the line.

Allow me to lay out some groundwork for you. VIBCO manufacturers industrial and construction vibrators with about 1800 finished items in our product line, over 46 patents, and 360,000 customers globally. We are in the MRO business – maintenance, repair and operation. In our business, when somebody calls they need it NOW. They don't need excuses, they don't need delays, they don't need anything else. They need product because we're holding up an operation, a process, people, and money. We're holding up a lot of things that matter in the contracting world.

“Back in 2000 we didn't have clarity of what our true north was. We didn't have a deep understanding that when customers needed things, they needed them now,” explains Karl Wadensten, VIBCO’s CEO. “They didn't need complexity and confusion. They didn't need to concern themselves with that. All they needed to know was that we put the vibrator in the box and got the boxes out to them in the right quantity, at the right time, at the right price. I'm using these words explicitly because these are the things that customers want to know. Now that I've laid out a little background of our business you can see where VIBCO was nearly 20 years ago. This is the real story of how we obtained a deeper understanding into what our business culture really was and what our business wasn’t.”

Giovanni, working in our sales department had been speaking to the Customer throughout the entire week - even the week prior - and the conversation reached a fever pitch on Friday as it was the last work day of the week. With each call the customer placed on that Friday, you could tell by his voice he was getting more and more panicked. He sensed with the answers Giovanni was giving him that the order was not going to ship even though we had been telling him ‘we're trying to ship this out.’ We were trying, but we’d missed numerous promises before.

As Giovanni tells it, “Once I realized that it was not going to happen, I had to, in good conscience, tell him the truth. The final bell was ringing, employees were clocking out, and we didn't have any anymore time. I wanted to tell the Customer that, hey, we tried but there's nothing else we could do to get it out today. That's when he began to get very upset - not in anger but with sadness - and he literally broke down and cried. I started crying as he explained to me that he had a good friend that was an engineer on the job that had recommended him for the project.” The engineer had vouched for him and stood up for the Customer’s company and the VIBCO products he could deliver which were exactly what was needed for this bridge construction job. The Customer’s integrity was on the line and he was distraught.

“It was tough to hang up the phone. I felt like it was a 911 call and I should just be there for him,” explained Giovanni. “He finally realized that it wasn't going to happen and said goodbye.”

Giovanni had plans to go out to a quarterly lunch with the shipping group of 6 other workers. On the way to lunch, the crew was talking about the Customer’s job and Giovanni said, “You know, we should call Chief (their nickname for Karl, our CEO). Karl had bronchitis, so we labored on whether or not we should even contact him, but I left a voicemail and within about three to four minutes he had called back and he said, ``I got your message.”

Karl remembers the conversation as if it were yesterday. Giovanni said, “Chief, you won’t believe what happened to me.”

As I'm laying in bed I replied, “Giovanni, I'm sick. I don't have time for the guessing game. What happened to you?” Giovanni said, there was a grown man crying on the phone to him. And I said, “Come on, Gio, a grown man crying to you on the phone?”

Giovanni continued to explain that the Customer’s relatively small vibrator order was going to hold up a billion dollar bridge project. He was sad. He was crying and Giovanni said that in all his time here at VIBCO a customer had never literally cried over the phone to him. Karl told the shipping group to finish their meals and meet him back at the factory and call whoever you can to get back to the VIBCO factory to try and deliver the job.

We had one person de-blurring, Karl did welding, Giovanni feted pieces and parts for them because there were brackets and other accessories that needed to be fabricated and packaged to go along with the vibrator units. “I remember how sick Chief was and how he did what he did, what he could do, so that we could ship them out so they'd be there for Monday,” Giovanni said. “There was a lot that needed to be done.”

Our culture journey began that day with Giovanni having empathy and concern for a customer, and being clear and honest with the customer. Giovanni was stuck in a process that wasn't delivering the outcomes that our customers expected or needed. That was Giovanni's defining moment.

“My defining moment,” says Karl, “was taking the call, being sick as a dog at home, and listening to Giovanni's dissertation. I could hear the distress in Giovanni's voice and his real concern for our customer and our inability to help him. The Customer was worried about his engineer friend who stepped up for him. He was worried about his co- workers losing their jobs because they were awarded the bid to this nearly billion dollar project and couldn’t deliver, and worried that their organization had lost face with the prime contractor when they couldn't even deliver the most essential part, VIBCO vibrators. My defining moment with all that in the back of my mind, came as I was listening to Clark the shipping supervisor who was looking for help and how Giovanni was looking for help. I could have said, ‘guys, don't worry about it. I'm too sick. I'm not coming back,’ but at that point, I had tremendous faith and trust in Giovanni as well as Clark. I wanted these guys to have confidence that they could reach out to me and that I could help or at least bring some kind of relief and response to the problem.”

That's when Karl asked Giovanni and Clark to call whoever they could on a Friday afternoon and get them back into work. “When I came through the door, we had a small group of people assembled to take a look at what happened with this order,” explains Karl. “We weren't worried about what happened before but we needed to look at the current state of the order – where it was in the fabrication process. I remember thinking, ‘we’re a manufacturing company,’ so it's not just making one widget. We have 1800 widgets and we have just as many accessory items and the Customer ordered a combination of products to get things done. We had some of the components finished in some areas, some were half-done and some were not even started so it was a potpourri of things that were executed and non executed. We had to do a quick assessment of the project, assign duties and tasks, and just get to work on this.”

There's one other piece that is critical. Giovanni called the Customer back and said, “The president of the company knows now. We’re going to get this product to you.” Giovanni called the Customer back. That's a key thing. Giovanni reached out.

“The defining moment for me,” added Karl, “was that Giovanni put his honesty, integrity on the line for this Customer, assuring him that something was going to get done. I couldn’t just leave it like that – I couldn't let Giovanni down like that – I couldn't let the customer down like that. It becomes a big ripple effect of people that are disappointed and frustrated. I couldn't, I couldn't, I had to break the cycle, and now, my word was on it.”

The loyal VIBCO employees who came back that Friday started working at lightning speed on this order. The welder didn't come back but Karl had been trained in welding. Even with severe bronchitis, he put on a welding hood and respirator and started welding. Giovanni, Clark and the others assembled these pieces and did all the things that we needed to do.

“All the while we are working on this, there's one underlying critical detail. The UPS plane leaves at 7:00pm on Friday evening,” explains Karl. “We had to get Billy and everybody else at UPS to help us out. It just didn't happen – it wasn't a standing process. We were 30 minutes away from the airport and we started midday working on this order, putting in the final touches to get this order ready to go on-time.”

The loyal VIBCO crew had the last box buttoned up 6:32pm. “So 30 minute ride to the airport, the plane leaves at seven, do the math– 7:02 – barring no traffic on a Friday night in New England. At that point, thank God, Rhode Island is a place, the smallest state in the union, where you know a guy! We knew the guy, Billy, that was the head of logistics and sales for UPS and on our drive up there, I was dialing his number frantically saying that I was on my way. “You’ve got to hold the plane.” You've got to hold the plane because now my word, Giovanni's word and the hope of all our people here at VIBCO was that this is happening tonight.”

We couldn't let the Customer go into the weekend not knowing what was happening. We couldn’t call back again saying we missed the plane. That wasn't going to happen. The sense of urgency wasn't one person's urgency, it was a village of urgency.

“I had to quickly review with UPS that my name was on this at this, this was happening.” I said, “Billy, whatever you gotta do.” We knew a guy, we got the right guy and I said, “You've got to hold that plane. You've got to figure out how to hold the plane,” Karl pleaded, “and whatever Billy did that night, that plane was held and we made it there at 7:03pm. They were checking in boxes as they were loading them onto the cargo bay of the plane.”

This is where the reflection takes place. Karl drove back to the shop right after the delivery to the small crew of warriors that made this happen – who understood the urgency, understood the integrity, understood that we all had our names to this, that this was going to happen. “I would have figured that we'd be celebrating like we just won the Super Bowl. I walked into the factory and it was just long faces because we knew that this wasn't a winning strategy to gain customers and retain customers. We knew that we had let this guy down three times before. It wasn't individual people that had let him down. It was our process,” Karl explained.

At VIBCO, we didn't understand how our process worked. It wasn't because people weren't trying. It wasn't because people didn't want to work hard. We didn't know, in the system, what we had to do to meet the expectations of all of our customers. We couldn't blame one person. It was a systems issue with us.

“I went back home to bed for the weekend. I took my medicine, and stayed in bed with bronchitis and the entire time I was laying there, I was thinking about what had just happened,” Karl reflected.

“As I drove to work the following Monday,” Karl recalled, “I questioned whether I was a good leader. How could this happen? We saw everything on the surface. It seemed that we were doing a good job and everybody's working hard, but the feedback and reflection from customers wasn't showing us that. I didn't know if I wanted to be the leader of an organization like this. Even though what we just did was Herculean and unbelievable, we weren't laying the track work for long-term sustained growth and holding up to our promises to customers. Did I want to run an organization where we didn’t, all of us, uphold the responsibility and promises to the customers every time, at all costs, no matter what? And if I didn’t want to be in that organization, why should my people want to be in that organization? These are key points. If we can't work together as a team and share and learn together, then it's not meant for me to lead this organization. That's when I was thinking of all the reasons that I didn't have the stamina or energy to go through my career to lead an organization that would do this again and again and again, unintentionally. Whatever success we attained would be marginal at best because long term sustained growth doesn't happen often without reflection or introspection of ourselves.”

“Then it hit me like a ton of bricks,” Karl revealed. “What we had to do to survive was this thing called Same Day, Next Day. It had to happen in VIBCO today, tomorrow in the truck, the next day at the customer.

This epiphany, that VIBCO’s a MRO, maintenance repair and operations business, returned. We did not have the clarity to see how time sensitive and how urgent our customers were when they called for help and needed suggestions. They needed it now, not tomorrow, not next week, not next hour.

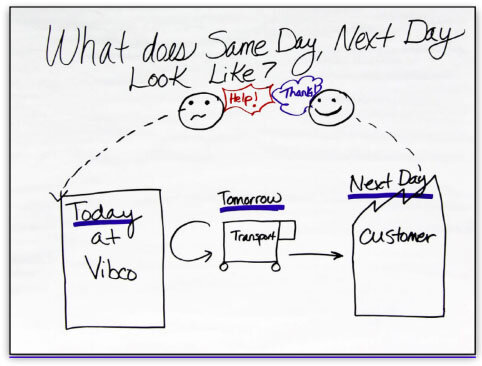

“We're pain relief for customers,” thought Karl. “As I drove in, I could see it clear as day this same day, next day notion. When I arrive at VIBCO that Monday morning, I circled all the employees. We met in the cafeteria and we discussed what had happened on that Friday while everybody was home for the weekend, having fun thinking that we were a hard working organization and feeling proud about the things we did right. We discussed and shared with them what happened with our Customer. I shared the heartfelt, heartbreaking story about how we let our Customer down. I shared the camaraderie and the ‘get to it spirit’ that we had all given to make this happen and talked about our process. Everybody looked at me with blank faces. They didn't understand. Whether it was the medicine I was taking, whether it was my description of the problem, they just sat there and looked at me with blank faces. I wrote Same day, Next day on the board. I could see it wasn’t resonating so I drew the picture on the board. I added the smiley faces with the ‘Help’ exclamation and then I showed the happy face. We take frowns and we turned them upside down. I drew a picture of our factory (Same Day), a picture of the truck (tomorrow), and I drew a picture of the customer’s factory (Next day). Then the light bulbs started going off and finally we, as an organization, began to see our mission.”

The original Karl Wadensten drawing of Same Day, Next Day

The sum of the pieces is greater than the whole. Everybody figured out what their pieces were. Some people had to do it the same minute next minute. Some people had to do it the same hour next hour and we started clicking. Even small steps over the course of the year would snowball into major changes. We had a lot of confusion. We got a lot of ambiguity. We actually had finger pointing too. There were people that wanted to finger point and the finger pointing was not going to get us out of this predicament that we were in, nor help with sustained growth.

Karl had joined the Young Presidents Organization (YPO) back in 1995 and he looked back at everything he had learned at YPO to seek improved ways to fix the problems at VIBCO (the original Fix What Bugs You). YPO is a global organization where the mantra is better leaders through learning and understanding. It’s a peer group of the top leaders meeting together, learning from each other and sharing, in a non-judgmental and non-confrontational way, their defeats, sharing their wins, sharing opportunities, and sharing from the heart and wanting to see people grow. Karl began asking questions like “How do we become authentic?” “How do we talk to each other.” “How do we surface the things that are bad without making people feel bad that we wanted to start attacking processes.”

“I knew that change had to start with culture,” Karl related. “I couldn't go in and look at our system and start fixing things because our culture needed to change deep down to the corners of the building and the employees, to each and every single one of us. We had to grow a culture in our organization, to tackle the things that would surface in the years to come.”

VIBCO started with training and the lessons in the book Fish Philosophy about the Pike Place Fish Market. The four basic premises for fish philosophy are:

#1, Choose Your Attitude. When you walk through the doors of the building, choose your attitude and make a proclamation of what your attitude is. If you had a rough day because you have a new baby and you didn't get the diapers your baby needed and you didn't sleep and you walk in grumpy, let people know that. Own up to it. If you had a rough night last night with a new baby make it clear you are not upset with co-workers. We want people to choose a positive attitude. When we walk into the building, no one's going to ask you to get diapers and no one is going to ask you to change a crying baby. You don't have to get up for a 2:00 feeding. We're all in this together to do our MRO business. Choose your attitude.

#2 is Be Present. Turn on all your senses – listen, watch, talk, smell, taste. All those senses allow you to be present while you're here. Look for the opportunities and see the things we can fix. Share the bad things so we know where we can improve.

If every single one of VIBCO’s employees could be world-class, no matter what our version of world class is, tomorrow would be better than where we are today. You may think being world class is holding your snowboard over your head in British Columbia and cheering at the top of your lungs because you just did something crazy. You may think world class is that you just did a great dinner party for your future in laws and everybody smiled and was happy. World Class means upping your game – being the best you can be.

#3 is Make Someone's Day. Sharing gratefulness. We have to make somebody's day, whether it was an internal customer or an external customer. Just say something nice, notice things, and acknowledge things. After we did all these steps, we could have fun at VIBCO.

#4 is Play. Embracing Fish Philosophy has made the lean journey much more fun and sustainable because it has engendered and inspired passion.

“So began the fun journey. I gave everybody the ‘Fish’ book that Christmas,” Karl recalled. “All kinds of other nice things went out, but everybody was kind of surprised that first year that they got a gift wrapped book. This fish philosophy was the beginning of a framework and a platform for us to think about. We didn't just read the book, we lived this and we still live in today, in 2018. This wasn't something we were going to do for just one year; This became core to our values and our beliefs.”

“Not long after we started practicing and living fish philosophy, I was invited to speak in Seattle,” Karl shared. “Well, lo and behold, Pike Place Fish Market is in Seattle, so I took my wife and my family and we went down to the famous fish market. It was all that the book wrote about. These guys were unbelievable. I came around the corner and there were dozens and dozens of people. There was loud noise, there was laughter, there was excitement. People were screeching and screaming and giggling and laughing. These guys were putting on a show like something you'd see on Broadway. I went up to the counter and I had the whole factory turn on Pike Place Fish Market. They were streaming live so they could see me and the family in the fish market, playing around with these guys, throwing fish, and seeing all the people there. The next day I told all VIBCO employees to assemble inside the factory and get rain gear on, get rubber gloves on, get safety glasses on. You should've seen the costumes that they had on that day. There was going to be a special package coming for them. There was a buzz around the factory of what was going to happen that day. I picked the biggest fish that I could find at Pike’s. I think it was about a 25 pound whole fish and I air expressed it to the factory.”

“What were you guys thinking,” Karl asked Big Jay from the shop.

“I had no idea. Honestly had no idea,” said Jay. “All the way up to the moment the package arrived, no one knew, so there was some kind of excitement and chatter of what the hell? What is going on tomorrow? When the fish arrived we had a competition for all of VIBCO for just throwing the fish. We started at a certain distance and then we kept backing off and backing off and I believe Kevin and I got to 30 feet apart. And it was a 25 pounder. It was a big boy. Yeah. That was a lot of fun. We just kept going through the teams. Just kept going until the end when everybody was cheering us. When we threw the fish really hard, it hit the fan so whether you were a spectator or participant, everybody got fished! It was a lot of fun. You know, definitely a lot of fun to bring another environment here. The core people here will always remember that day.”

The Fish arrives . . .

The saga of culture building continues at VIBCO. We had the “Happy to Do It” theme and that was really important. We have used many other learning tools such as “I Just Want My Pants,” “Staple Yourself to the Order,” “Who Moved the Cheese” just to name a few. We then moved on to Gallup’s Marcus Buckingham, and Clifton Strengths Finder, so we got to know our people more. “About four or five years later,” adds Karl, “once we had started to really develop our culture, that's when we began working with the lean operational tools. We started to understand each other and to work together as a team, only then we could we incorporate Toyota production systems into our group. And that is where our Lean Culture Journey really began.”

We started speaking a new Lean Language. We learned to see things differently using Ohno circles and Gemba Walks. We started to eliminate Muda (waste) and use best practices (lean/six sigma). After 18 years of practicing Lean Manufacturing, we are still continuously improving, growing and learning.

Everyday, all employees participate in a 10 minute morning stretch session, a 30 minute Kaizen blitz, and 5S to promote better wellness, fewer injuries and lower healthcare costs. This team time also provides an open forum for discussion and daily planning. Enthusiasm and willingness to “live it” are rewarded and recognized as we Shake the WasteTM and Fix What Bugs YouTM! This enthusiasm goes beyond the culture that has been created within VIBCO and extends to community groups, industry collaboration and tour groups.